Press Brake Sheet Bending Services | O'Donnell Metal Fabricators

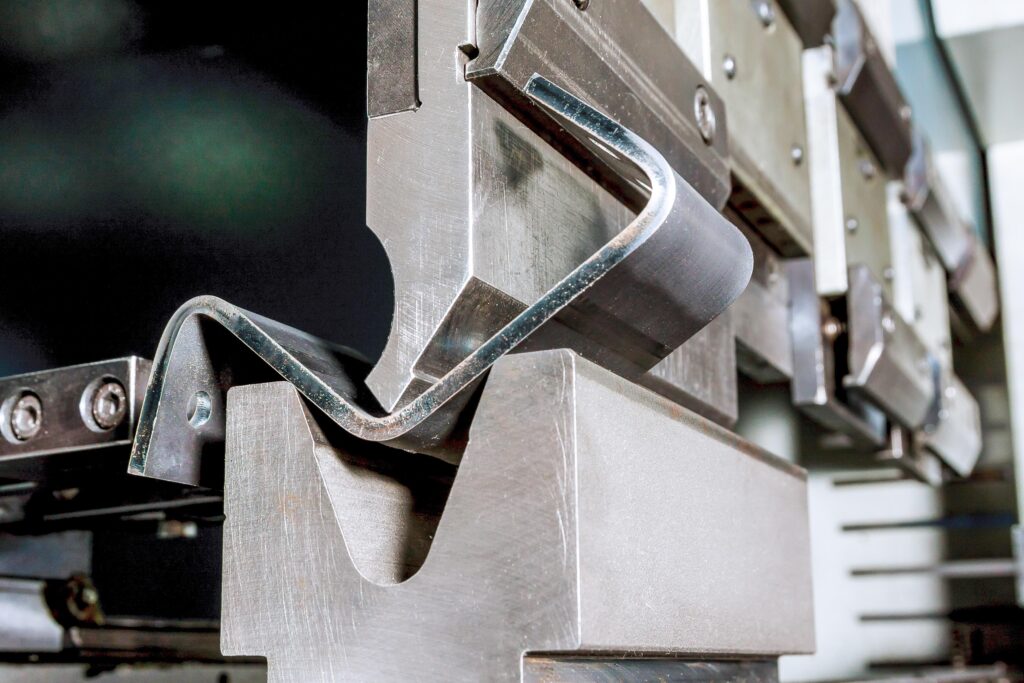

At O’Donnell Metal Fabricators, we specialize in precision press brake sheet bending, delivering high-quality, custom-formed metal components for a wide range of industries. Our Cincinnati 12′ press brake offers 175-ton capacity, allowing us to bend stainless steel, mild steel, and aluminum with tight tolerances and consistent accuracy.

Whether you need single or multiple bends, complex forming, or custom prototypes, we have the expertise and equipment to meet your specifications.

Precision Metal Bending for Custom Fabrication

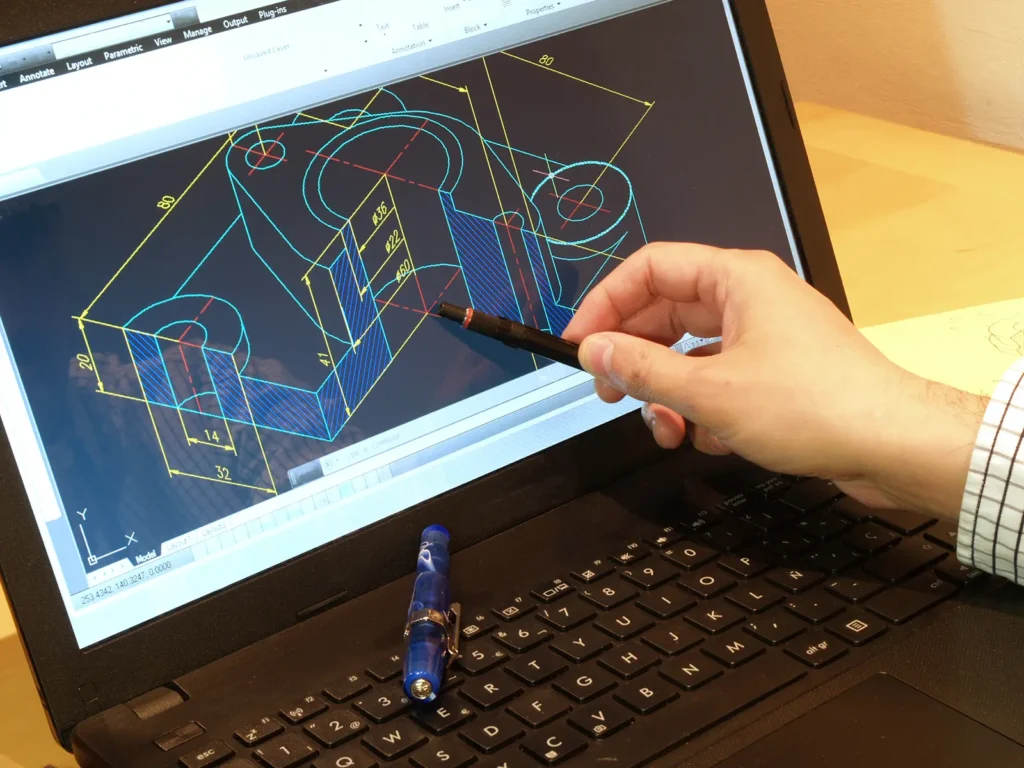

Our press brake metal bending services are ideal for industries requiring accurate, repeatable bends for custom fabrication. With advanced CNC press brake technology, we provide:

- Accurate and repeatable bends for large and small production runs

- Custom angles and radii for unique designs

- Consistent quality control to meet exact specifications

- Fast turnaround times for urgent projects

What Is Press Brake Sheet Bending?

How Press Brake Bending Works

Press brake bending is a metal fabrication process where a metal sheet is placed between a punch and a die, and then bent into a desired shape through force. This method allows for:

- High-precision bends with minimal distortion

- Complex part fabrication for enclosures, brackets, and panels

- Strong, uniform metal components with enhanced durability

Our Press Brake Capabilities

We offer custom sheet metal bending for a variety of applications:

- Machine: Cincinnati 12' Press Brake

- Tonnage: 175 Ton

- Bend Thickness: Up to 1/8" stainless steel, mild steel, and aluminum

- Types of Bends: U-bends, V-bends, air bending, bottom bending, hemming

Our press brake is ideal for creating precise, complex bends in a single operation, reducing production time and costs.

Materials We Work With

We specialize in bending a variety of metals, ensuring strength and durability for all projects:

- Stainless Steel – Corrosion-resistant and strong

- Mild Steel – Versatile and cost-effective

- Aluminum – Lightweight and durable

- Galvanized Steel – Rust-resistant and long-lasting

- Hot & Cold Finished Steel – Suitable for precision parts

Industries That Rely on Our Sheet Bending Services

Our press brake bending services support multiple industries, including:

- Aerospace – Precision components for aircraft and defense

- Automotive – Custom brackets, frames, and structural parts

- Medical Equipment – High-precision forming for medical devices

- Builder Hardware – Supports, enclosures, and panels

- Military & Defense – Heavy-duty, mission-critical parts

With our highly skilled metal fabricators, we ensure that every project meets industry-specific requirements.

Why Choose O'Donnell Metal Fabricators for Press Brake Bending?

Experienced Fabricators

Decades of expertise in custom metal bending.

State-of-the-Art Equipment

CNC-controlled press brakes for precision.

Fast Turnaround

Reliable production schedules to meet your deadlines.

Custom Solutions

We tailor every project to your exact specifications.

Frequently Asked Questions (FAQs) About Press Brake Bending

What is the maximum thickness you can bend?

We can bend up to 1/8″ stainless steel, mild steel, and aluminum using our Cincinnati 12′ press brake (175 Ton capacity).

What types of bends can you create?

We can perform a variety of bends, including V-bends, U-bends, air bending, bottom bending, and hemming.

Can you handle custom prototype projects?

Yes! We specialize in custom sheet bending for prototypes, one-off projects, and full production runs.

How accurate are your bends?

Our CNC-controlled press brakes ensure tight tolerances and repeatable accuracy, making them perfect for precision metal fabrication.

Do you offer additional fabrication services after bending?

Absolutely! We provide welding, CNC laser cutting, hardware insertion, and powder coating for a complete metal fabrication solution.

How do I request a quote for press brake bending?

You can contact us at (610) 477-6793, visit us at 315 W Germantown Pike, Norristown, PA, or submit a request via our Contact Page.

Request a Quote for Press Brake Bending Services

Looking for expert press brake sheet bending services? Contact O’Donnell Metal Fabricators today for a custom quote on your metal bending project.

Our Clients

With over 40 years of providing custom fabrication and sheet metal bending services, we continue to serve an extensive range of industries, including aerospace and aviation, automotive, industrial, military and defense, manufacturing, oil and energy, medical and pharmaceutical, and more.

Metal fabrication companies in the PA, NJ, DE, and MD areas should strive to be more than just service providers. At ODMF, we don’t just fabricate products; we engineer success. Our team is devoted to going above and beyond to provide the best solutions, not only in terms of material selection and fabrication precision but also in overall functionality. We dedicate ourselves to delivering quality products that are designed and manufactured to help our clients reach unprecedented heights in their field.

Trustindex verifies that the original source of the review is Google. Did a very nice job on a piece of custom ductwork I needed for a commercial kitchen project. Part was made exactly to my specifications. Jason Rosen did a great job communicating and making sure they understood the specs before doing the work. Will definitely use again.Trustindex verifies that the original source of the review is Google. This team is awesome & incredibly knowledgeable. They take genuine interest in their projects and will really take the time to make sure you get exactly what you want. I came in with a unique request and Jason & Tom couldn’t have been nicer and more helpful, and Michael O’Donnell is one of the best in the business. In a time where many services seem so transactional, it’s businesses like this that stand out. These guys are top notch & I’ll 100% keep going back for all my projects.Trustindex verifies that the original source of the review is Google. We contacted O'Donnell for stainless steel trays we needed on short notice. They delivered quickly and at a competitive price. Their team was a pleasure to work with, and we’ll definitely be returning as repeat customers!Trustindex verifies that the original source of the review is Google. Thank you all at O'Donnell Metal Fabricators with your help securing my table. Michael and Tom came up with a great plan and completed the project in a timely manner.Trustindex verifies that the original source of the review is Google. I entered their office and was greeted by Jason, a very bright and helpful person. It turned out that he was also a very good, considerate person. I went to this Metal Fabricating Company with a very unusual request. I was requesting a specially constructed hard, yet safe bed for my 8 month old puppy. He would chew all prior soft beds and eat the pieces that came off. I even went to a National chain hardware store and purchased a round aluminum base (usually used to be placed under a water heater in case of a leak.) Our dog loved laying in it and used it as his bed. He likes hard surfaces. This item however, since it was made out of tin, the puppy chewed completly around the edge and finally was able to chew off a piece that I had to grab before he swallowed it. That would have resulted in surgery for him to get this rough piece of metal out of him. So I thought if I could get the same design but made of iron or steel that he would not be able to chew it and swallow any pieces that may come off since I didn't think that would be possible. Jason, at O'Donnell actually showed me what they could make for my pup and quoted me a written cost. He however cautioned me to check with my dog's Vet. to assure that he wouldn't break any teeth. I did that and the Vet told me not to try it since they couldn't guarantee that his permanent teeth wouldn't break. Here is a Company that could have had a sale with me but their their representative Jason proved that he is principalled, kind and thoughtful and thought about the customer first. He is the kind of person and obviously represents the kind of Company that one can trust, knowing that when you do business with them, you'll get a good product from very conscientous people. Kudos to them along with my high recommendation. PWTrustindex verifies that the original source of the review is Google. We can't recommend O'Donnell Metal Fabricators highly enough for anyone in search of a custom steel fire pit insert. Their professionalism, expertise, and turnaround time are second to none!Trustindex verifies that the original source of the review is Google. McMenamin's Tavern has been working with O'Donnell Metal Fabdrications since 1997! Their service and quality of work has always been outstanding. Thank you for your continued excellent service and professionalism! We appreciate your care and commitment. Thanks for your urgency in fixing a repair for us this month to enable us to continue business as usual.Trustindex verifies that the original source of the review is Google. I have been dealing with O'Donnell Metal Fab for about 3 years and their service and quality of work have been exceptional and they will go the extra mile when possible.Trustindex verifies that the original source of the review is Google. Just had this group do an install of a Restaurant hood system in New Jersey. This company is first class all the way. Mike was a great guy to work with and communication with the contractors were on point. The fire inspectors raved about the job they did and said "I wish these guys did all the installs around here", I will use them again on future installs.Google rating score: 4.8 of 5, based on 13 reviewsVerified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more