CNC Fiber Laser Cutting in the Greater Philadelphia Area

When you need metal parts with precise dimensions and cuts, our CNC fiber laser cutting services in the Greater Philadelphia area can deliver. Our advanced laser cutters will keep production running smoothly while satisfying your customers with high-quality products and short turnaround times. We guarantee precision, durability, and reliability whenever you partner with our CNC laser cutting experts.

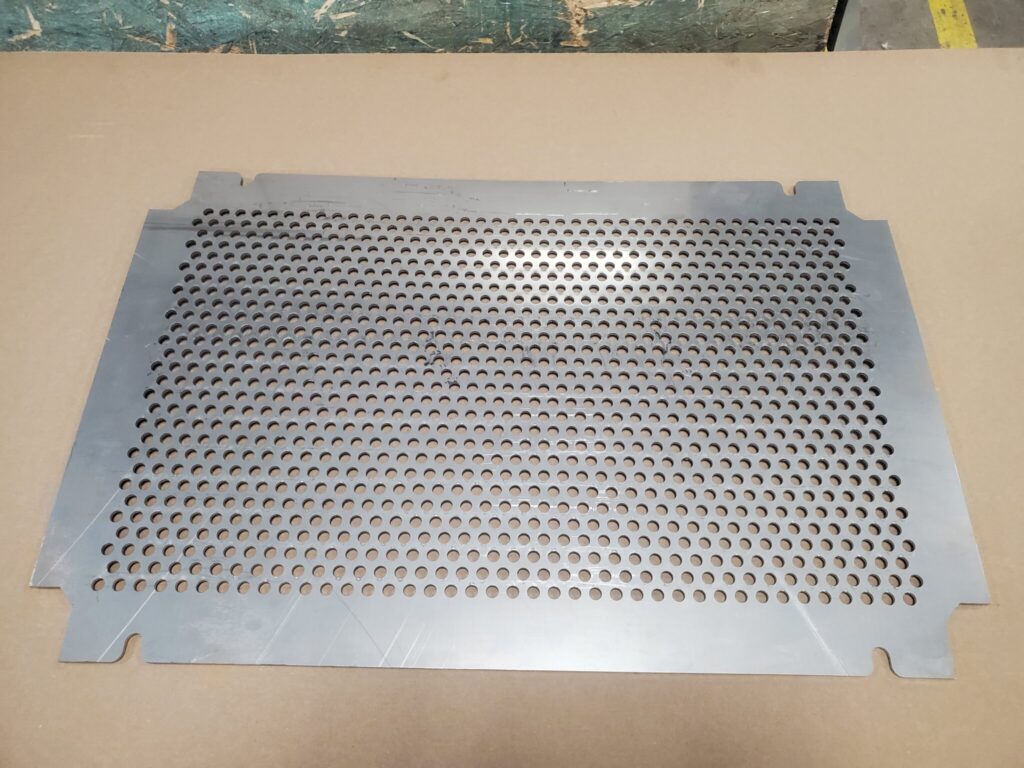

From initial-design prototypes to production runs of any size, O’Donnell Metal Fabricators offers sheet metal laser cutting services with competitive prices and precise results. Laser cutting provides a narrow, clean kerf with close tolerances (+/-.005″). Without dies, the setup is quick, and changes to parts can be processed easily. Our offline nesting software will allow your custom-designed parts to be made efficiently and accurately. Request fiber laser cutting prices in PA, NJ, DE, and MD today!

How Metal Laser Cutting Works

Over the years, manufacturers have noticed an increasingly strong demand for sophisticated machining technologies. Computer numerical control (CNC) machinery was introduced to fill this need. CNC fiber laser cutters are one such piece of equipment used to meet stringent process requirements. These advanced pieces of machinery use a high-powered laser beam to cut stainless steel, galvanized steel, and aluminum. The fiber laser’s unique capabilities make it possible to create small holes and intricate shapes with extreme accuracy.

Our CNC fiber laser cutting services in Greater Philadelphia utilize the latest technology to meet our client’s exact specifications. Our fiber laser machines feature a bank of diodes to create a beam focused through a fiber-optic cable. This beam provides a faster and cleaner cut than other types of laser cutters and eliminates the need for additional post-processing operations and other cutting tools. Our CNC laser cutting processes are ideal for materials less than 5mm thick. If you’re ready to experience the power of fiber lasers, choose the team with over 45 years of experience fabricating parts precisely and accurately.

The Many Advantages of Fiber Laser Cutters

The precision and high speed of metal laser cutting have made it a popular choice for manufacturing in an array of industries. More and more manufacturers are turning from other cutting methods to reap the many benefits of fiber laser cutting machines. From improved quality to lower operating costs, there’s much to be gained from implementing fiber laser cutters into your manufacturing process.

When you choose our CNC fiber laser cutting services in Greater Philadelphia, you can expect the following:

Accuracy

The focused laser beam cuts through metal at high speed, providing precise lines.

Cost-Effective Solutions

Fiber laser machines can operate quickly and efficiently, shortening your production time and cutting costs.

Fast Prototyping

Fiber lasers produce clean cuts the first time and minimize operator errors so that you can create more accurate prototypes in less time.

Our certified experts specialize in fiber laser technology and can help determine if CNC fiber laser cutting is right for your Greater Philadelphia business. From small, intricate metal parts to larger items, we’re ready to handle all your metal fabrication needs.

Read More

Are Fiber Laser Cutting Machines Right for Your Application?

If you’re considering fiber lasers for your upcoming project, you may be weighing the pros and cons of this type of cutting method compared to plasma cutting. How do you know which cutting technology will allow you to meet your production requirements? It comes down to several factors, including material type and thickness, the accuracy of cuts, and cutting speed.

Both plasma and fiber laser cutters can cut through an array of metals, including reflective metals such as aluminum and copper. However, a fiber laser cutting machine can only cut materials up to a certain thickness; otherwise, more power is needed, and this translates into greater costs. If your metal’s thickness is between 25mm and 1 inch, a fiber laser cutter is ideal.

When it comes to accuracy, CNC laser cutting machines are the best option, as they can cut metal extremely accurately and quickly. If you are only cutting simple shapes, a plasma laser can often meet your needs at a much more affordable cost. Although, you must take into consideration the fact that plasma cutters are much slower, which may affect your overall production time.

When you request a quote for our services, we will examine the particulars of your project to determine the best type of method for achieving your goals. Whether that’s laser cutting, plasma cutting, or even bending, you can trust we will provide quality results. We use only the best metal laser cutting materials to create durable products that withstand the test of time.

Speak With Our Team Today

When it comes to precision cutting, no team is more suited for the job than O’Donnell Metal Fabricators. Our experts have had specialized training in metal laser cutting materials and machinery and will ensure your project is completed on time and without errors.

Reach out to our specialists today to request a quote on CNC fiber laser cutting in Greater Philadelphia and the surrounding communities in PA. We also serve businesses in NJ, DE, and MD, so don’t hesitate to see how our fiber laser cutters can benefit you.